Automatic wire drawing machines have significantly advanced the manufacturing process, offering efficiency and precision in the production of wires. To maximize the performance and longevity of these machines, and to ensure user safety, it is essential to follow certain precautions. In this article, we will detail the necessary measures when using the automatic wire drawing machine, specifically addressing the needs for pre-operational checks, safety measures, regular maintenance, and common issue resolutions.

Pre-Operational Check for Wire Drawing Machine

Before initiating the operation of an automatic wire drawing machine, it is crucial to undertake several pre-operational checks to ensure the machine's optimal performance and the safety of the operator.

1. Inspect the Machine: Start by thoroughly inspecting the machine for any visible damages or signs of wear and tear. Check for loose bolts, damaged parts, and ensure that all protective covers are in place.

2. Lubrication: Proper lubrication is vital. Check the lubrication levels and ensure that all moving parts are adequately lubricated. This prevents excessive wear and extends the life of the machine.

3. Electrical Connections: Ensure that all electrical connections are secure. Look for signs of fraying or damaged wires which could pose safety risks.

4. Confirm Settings: Verify that the machine settings match the material specifications you are about to work on. Different materials might require specific settings; for instance, parameters set for drawing copper wire might differ from those for steel.

5. Test Run: Conduct a short test run without any material to ensure that all components are functioning correctly. Listen for unusual sounds that could indicate potential issues.

Safe Operation of Wire Drawing Machine

Operating an automatic wire drawing machine requires adherence to strict safety measures to protect the operator and maintain the integrity of the machine.

1. Personal Protective Equipment: Always wear the appropriate PPE, including safety glasses, gloves, and protective clothing. For operators of vertical wire drawing machines, additional safety harnesses may be necessary depending on the set-up.

2. Emergency Stops: Familiarize yourself with the location and operation of emergency stop buttons. These are crucial for immediately halting the machine in case of an emergency.

3. Clear the Area: Keep the working area uncluttered. Remove any unnecessary tools or materials that could obstruct operation or pose tripping hazards.

4. Monitor the Process: Continuously monitor the wire drawing process. Be alert for any irregularities such as abnormal noises, excessive vibrations, or deviations in wire dimensions.

5. Two-Man Rule: For intricate operations or those involving large equipment like the inverted vertical wire drawing machine, it is wise to have a second operator or supervisor present.

Maintenance of Wire Drawing Machines

Regular maintenance is essential for ensuring the longevity and efficiency of your wire drawing machine, as well as for the production of high-quality output.

1. Routine Cleaning: Regularly clean the machine to remove any dust, debris, or lubricant buildup. This prevents potential malfunctions and maintains operational efficiency.

2. Lubrication Schedule: Follow a strict lubrication schedule based on the manufacturer's guidelines. Over-lubrication can be just as detrimental as under-lubrication.

3. Component Inspection: Periodically inspect critical components like bearings, dies, and rollers. Replace any parts showing signs of excessive wear.

4. Software Updates: For technologically advanced machines, ensure that the software is regularly updated to the latest version provided by the manufacturer.

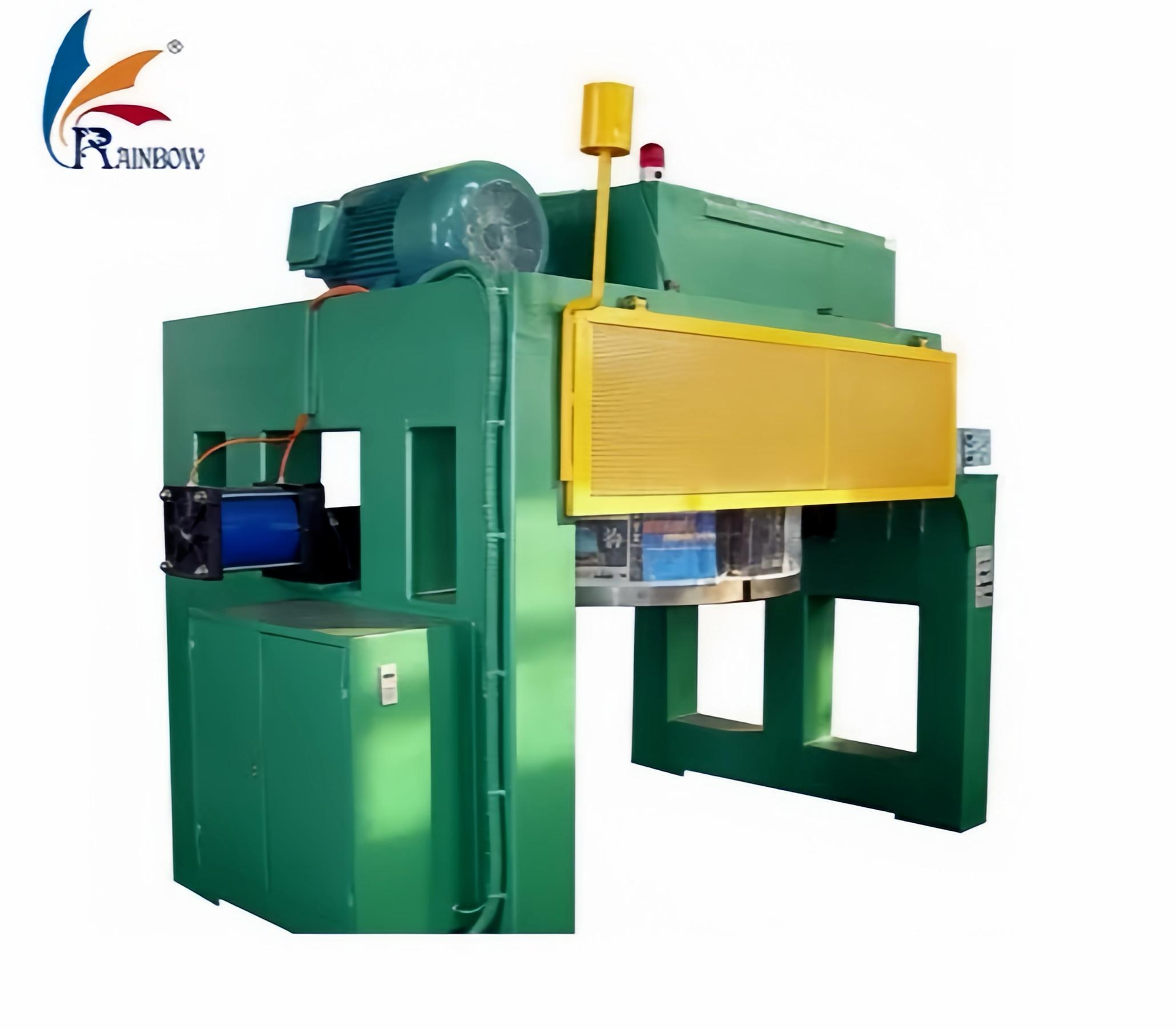

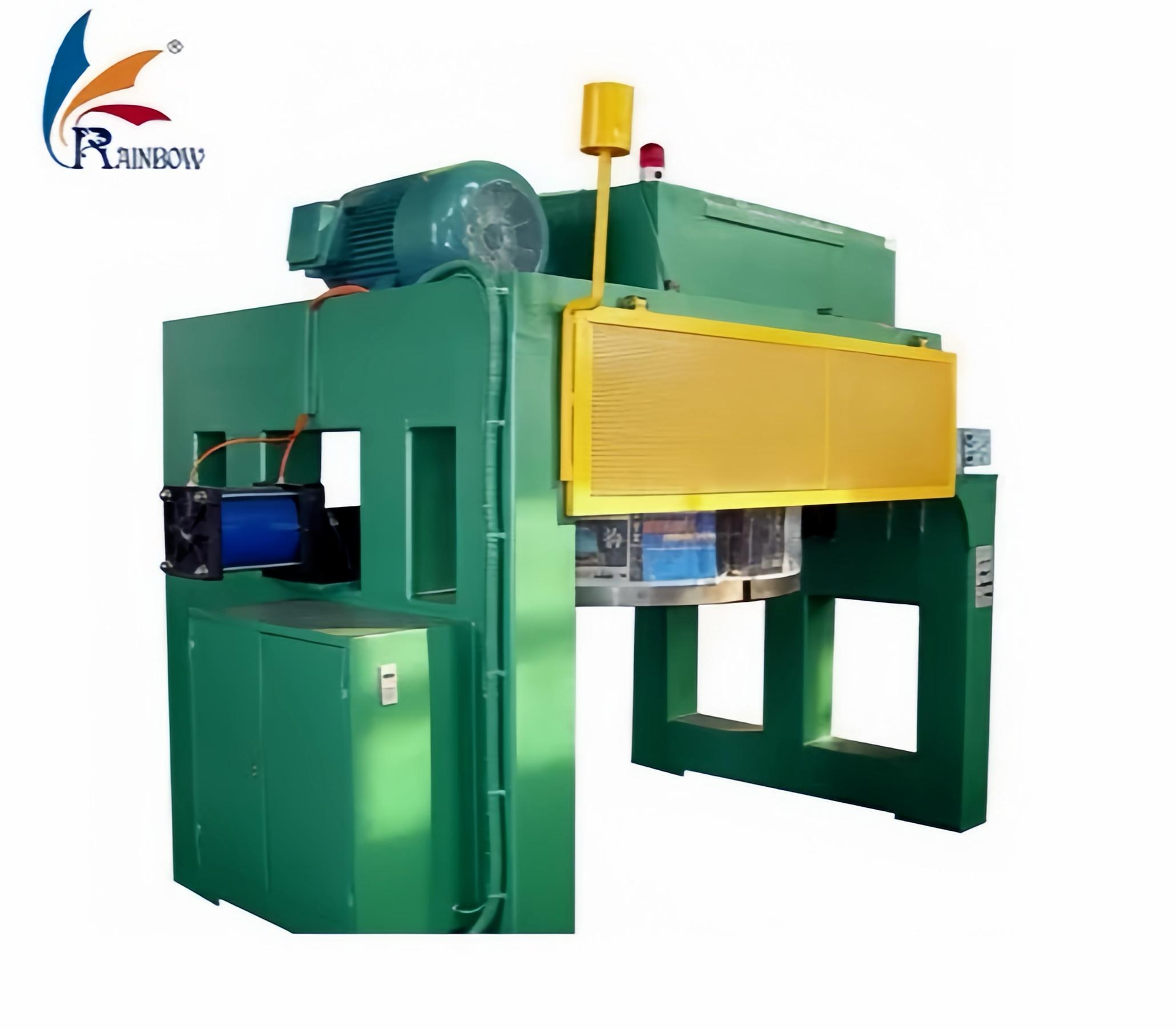

5. Professional Servicing: Schedule professional servicing with the manufacturer or an authorized service provider. Copper wire drawing machine manufacturers like Rainbow Fastener Machine often offer maintenance packages that include comprehensive checks and replacements.

Common Issues and Solutions of Wire Drawing Machine

Despite all precautions, issues may occasionally arise. Understanding common problems and their solutions can minimize downtime and repair costs.

1. Wire Breakage: One of the most common issues is wire breakage. Ensure that the feed rate is appropriate for the material and that the die is correctly aligned and in good condition.

2. Surface Defects: Surface defects on drawn wires can result from impurities or improper lubrication. Regularly clean the dies and ensure the use of high-quality lubricants.

3. Vibration and Noise: Excessive noise or vibration can indicate misaligned components or worn-out parts. Check the alignment of all moving parts and replace any that are overly worn.

4. Inconsistent Wire Diameter: If the wire diameter is not consistent, calibrate the machine settings and inspect the dies for wear or damage.

5. Overheating: Overheating can be a sign of poor lubrication or excessive operational speed. Ensure that the machine is adequately lubricated and that speed settings are within the recommended limits.

The efficient and safe operation of an automatic wire drawing machine, including vertical wire drawing machines and those tailor-made by manufacturers like Rainbow Fastener Machine, relies on thorough pre-operational checks, diligent adherence to safety measures, regular maintenance, and prompt resolution of common issues. By incorporating these precautions, operators can not only protect themselves and their equipment but also ensure the production of high-quality wire efficiently and cost-effectively.

English

English français

français Español

Español русский

русский português

português